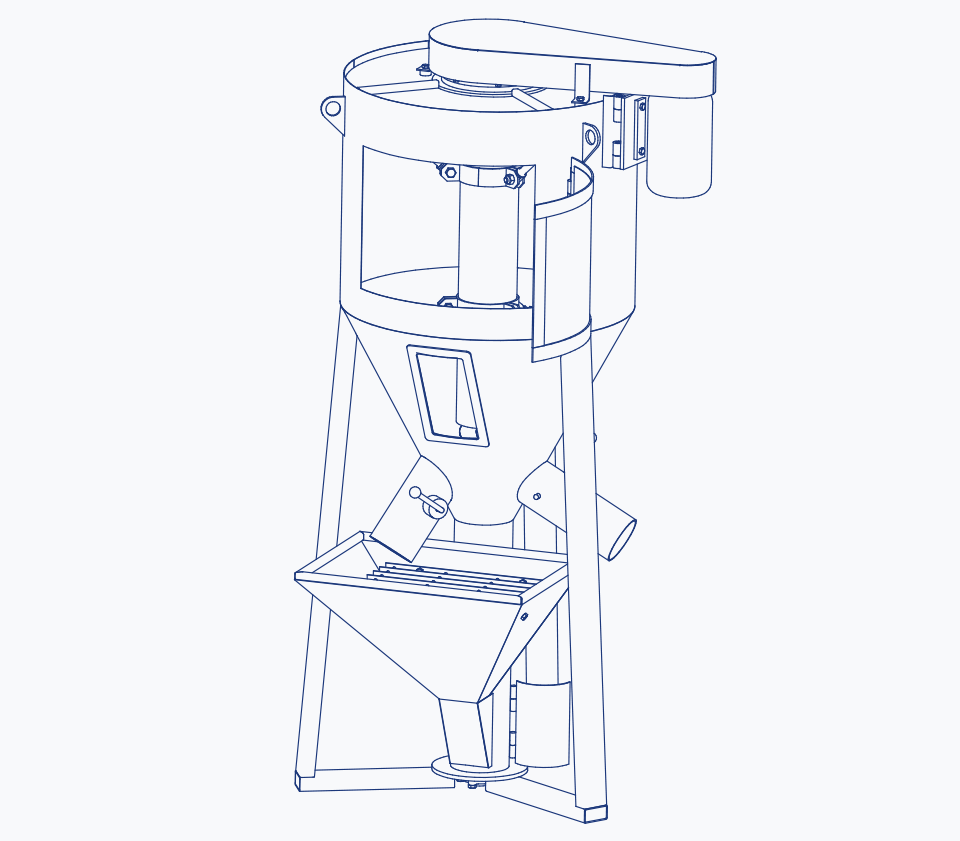

We manufacture mixers to provide uniform introduction of additives such as chalk concentrate (chalk additive), colorant, processing additives, and secondary raw materials, into the composition of polymer granules.

Operation: each mixer is equipped with a filling pocket for manual or automatic loading of raw material. With the mixer turned on, loading is carried out to a level that can be controlled through the windows located on the mixer cone. It takes 10-15 minutes to complete the mixing. The mixture seems to gush out inside the bunker.

Our mixers offer the following benefits:

— Easy operation and maintenance;

— Mixing homogeneity of 98%;

— Mixing virgin and recycled raw materials;

— Uniform coloration of granules (when colorants are added);

— 12 months warranty;

— Robust and wear-resistant screw;

— Container geometry eliminates “dead” zones, which ensures uniform and efficient mixing of the filled components.

Other options:

— Wheel stops (models LVGran-0.5 and LVGran-0.25);

— Timer control panel;

— Load cells to measure the weight of raw materials;

— Whether requested by the customer, we can increase the loading height of the material container, as well as install discharge outlets for pneumatic unloading.

* — loading (kg) is calculated based on the bulk density of raw materials – 0.5-0.6 g / cm3

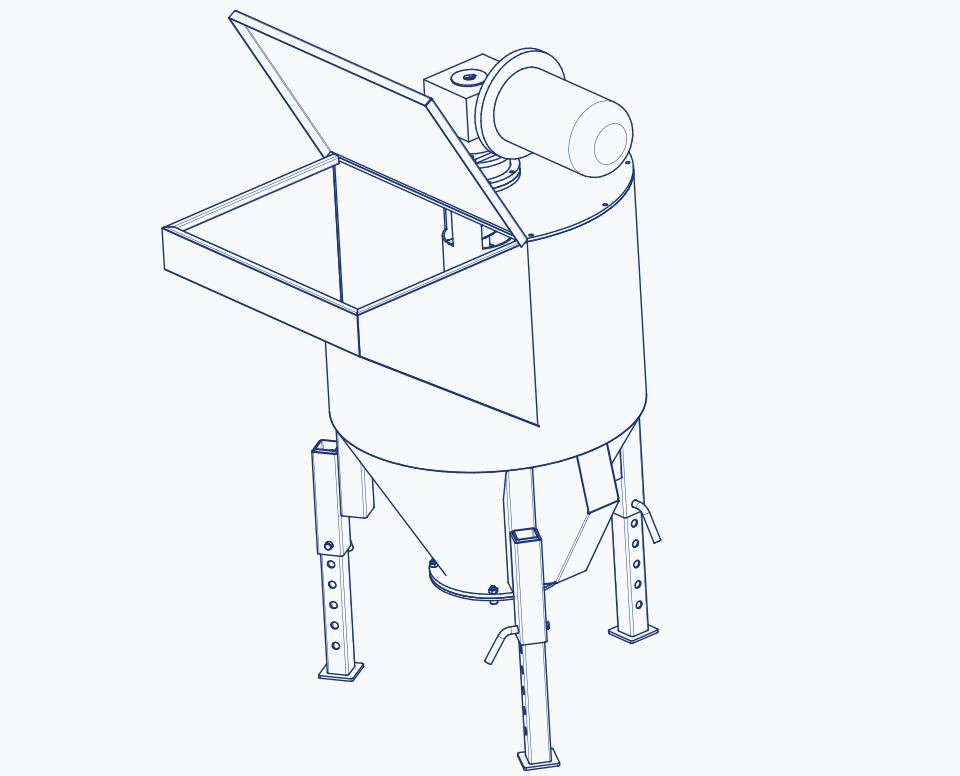

We manufacture mixers to provide uniform introduction of additives such as chalk concentrate (chalk additive), colorant, processing additives, and secondary raw materials, into the composition of polymer granules.

Operation: each mixer is equipped with a filling pocket for manual or automatic loading of raw material. With the mixer turned on, loading is carried out to a level that can be controlled through the windows located on the mixer cone. It takes 10-15 minutes to complete the mixing. The mixture seems to gush out inside the bunker.

Our mixers offer the following benefits:

— Easy operation and maintenance;

— Mixing homogeneity of 98%;

— Mixing virgin and recycled raw materials;

— Uniform coloration of granules (when colorants are added);

— 12 months warranty;

— Robust and wear-resistant screw;

— Container geometry eliminates “dead” zones, which ensures uniform and efficient mixing of the filled components.

Other options:

— Wheel stops (models LVGran-0.5 and LVGran-0.25);

— Timer control panel;

— Load cells to measure the weight of raw materials;

— Whether requested by the customer, we can increase the loading height of the material container, as well as install discharge outlets for pneumatic unloading.

* — loading (kg) is calculated based on the bulk density of raw materials – 0.5-0.6 g / cm3