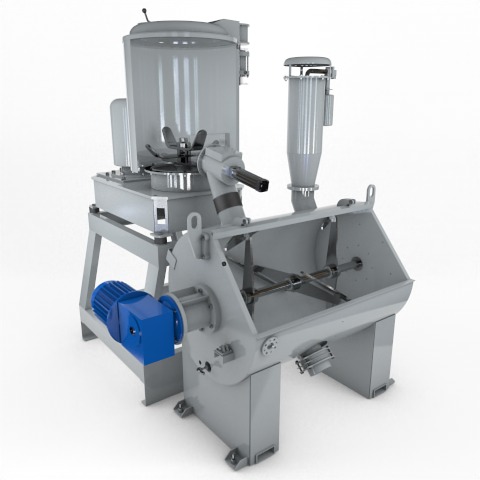

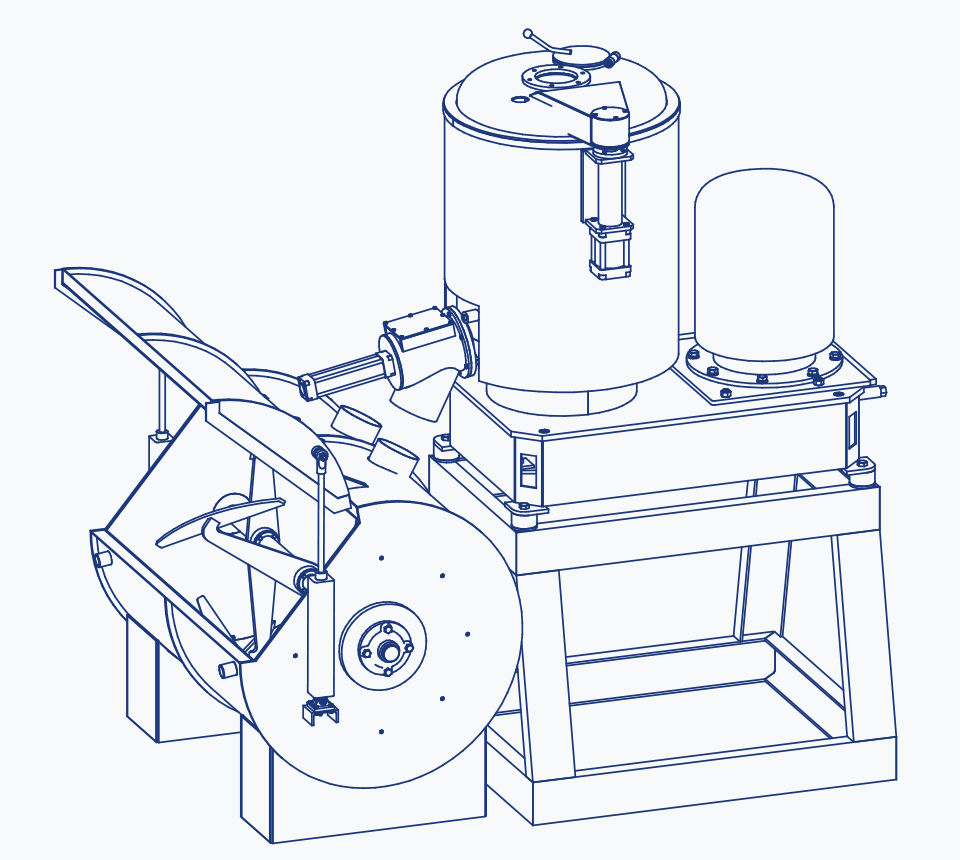

PVC mixer is an indispensable equipment in PVC production. The machine is used for mixing PVC with various additives such as heat stabilizers, plasticizers, lubricants, colorants, etc. As long as a compound is self-made, this will reduce the material cost by 10-15%.

The mixer has an upper hot mixer and a lower cooling mixer, a support frame and controls. Hot PVC mixer is used for mixing composition until homogeneous at a temperature of 120-140 degrees. It represents a tank with blades at the bottom, where due to friction, PVC is combined with chalk and a masterbatch. After that, a composition is discharged into the cold mixer to be cooled up to 40 degrees. We offer cold mixers in horizontal format. Сooling is made due to heat exchange with the mixer walls and the blades slow motion. The cold mixer has two tanks inserted into each other with water circulating between them.

— to use different loading / unloading and mixing speeds;

— to select the loading frequency of the components according to specified parameters;

— to collect system statistics;

— and solve other production tasks.

For processing high solids, we offer a set of 4 special geometry blades with wear-resistant ceramic coating.

PVC mixer is an indispensable equipment in PVC production. The machine is used for mixing PVC with various additives such as heat stabilizers, plasticizers, lubricants, colorants, etc. As long as a compound is self-made, this will reduce the material cost by 10-15%.

The mixer has an upper hot mixer and a lower cooling mixer, a support frame and controls. Hot PVC mixer is used for mixing composition until homogeneous at a temperature of 120-140 degrees. It represents a tank with blades at the bottom, where due to friction, PVC is combined with chalk and a masterbatch. After that, a composition is discharged into the cold mixer to be cooled up to 40 degrees. We offer cold mixers in horizontal format. Сooling is made due to heat exchange with the mixer walls and the blades slow motion. The cold mixer has two tanks inserted into each other with water circulating between them.

— to use different loading / unloading and mixing speeds;

— to select the loading frequency of the components according to specified parameters;

— to collect system statistics;

— and solve other production tasks.

For processing high solids, we offer a set of 4 special geometry blades with wear-resistant ceramic coating.